MARSEN

Level

- CARGO TANK MONITORING SYSTEM MODEL : CARGO-2000 (RADAR TYPE)

- CARGO TANK MONITORING SYSTEM MODEL : CARGO-2000 (MAGNETIC FLOAT TYPE)

- PRESSURE MONITORING SYSTEM MODEL : VIP-2000

- CARGO TANK HIGH / OVERFILL ALARM SYSTEM MODEL : HAI-2000 (MAGNETIC FLOAT TYPE)

- BALLAST TANK & DRAFT LEVEL GAUGING SYSTEM MODEL : BAL-2000 (ELECTRO PNEUMATIC TYPE)

- BALLAST TANK & DRAFT LEVEL GAUGING SYSTEM MODEL : BAL-2000 (ELECTRIC PRESSURE TYPE)

Product

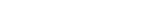

PRESSURE MONITORING SYSTEM

MODEL : VIP-2000

- GENERAL INFORMATION

- PRESSURE MONITORING SYSTEM is designed for monitoring the pressure of cargo tank or manifold.

- The Rules that cargo tanks ullage space monitoring system including high & low pressure alarm are newly required by IMO SOLAS 74, Chap. II Reg. 59 became effective 1st July 1998 for preventing the serious deformation of the tank structure caused by change of cargo tank pressure due to the failure of the P/V valve.

FEATURE & ADVANTAGE

- High accuracy

- Possible to install regardless

of the number of cargo tank - Two types to monitor the pressure of tanks or manifolds (Individual type & Collective type)

APPLICATION

All kinds of oil & chemical tankers

OPERATION PRINCIPLE & SYSTEM COMPOSITION

VIP-2000 is composed of pressure transmitters, control panel for monitoring the measured value by touch panel and barrier for ex-proof.

The transmitter measures the pressure by means of a semi-conductor sensor.

The electrical signals from the pressure transmitter are connected to barrier.

Then the signals are sent to the monitoring panel that is equipped with pressure alarm lamp & buzzer and LCD display in the cargo control room.

transmitter are connected to barrier.If the owner wants to add the function for measuring temp., it is possible to add temp. sensor.

TECHNICAL SPECIFICATION

- SUBJECT

- SENSOR TYPE

- SENSOR MATERIAL

- MAX PRESSURE

- MEASURING RANGE

- WORKING TEMP

- ACCURACY

- IP GRADE

- EX PROOF

- SIGNAL

- GAS KINDS

- DISPLAY

- SPECIFICATION

- Diaphragm type pressure transmitter

- SUS 316L/PTFE

- Up to over pressure (range X2)

- 500~1500mbar / 0~16bar

- -20 ~ 150°C

- ±0.5% of F.S (or user's request ±0.25% of F.S

- IP 68 (with housing)

- Ex ia IIC T6

- 4~20mA analog signal

- Oil/chemical

- Touch Screen

COMPONENTS / OUTLINE